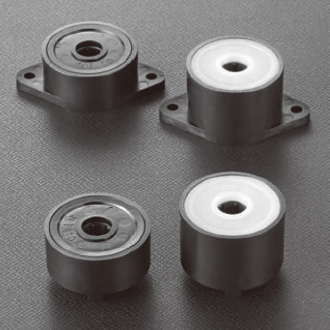

| Model | Max. torque | Damping direction |

|---|---|---|

| FFD-28FS-R102 | 0.1±0.01[N•m] (1±0.1kgf•cm) |

Clockwise |

| FFD-28FS-L102 | Counter-clockwise | |

| FFD-28FS-R502 | 0.5±0.05[N•m] (5±0.5kgf•cm) |

Clockwise |

| FFD-28FS-L502 | Counter-clockwise | |

| FFD-28FS-R103 | 1±0.1[N•m] (10±1kgf•cm) |

Clockwise |

| FFD-28FS-L103 | Counter-clockwise | |

| FFD-28FW-R103 | 1±0.1[N•m] (10±1kgf•cm) |

Clockwise |

| FFD-28FW-L103 | Counter-clockwise | |

| FFD-28FW-R153 | 1.5±0.15[N•m] (15±1.5kgf•cm) |

Clockwise |

| FFD-28FW-L153 | Counter-clockwise | |

| FFD-28FW-R203 | 2±0.2[N•m] (20±2kgf•cm) |

Clockwise |

| FFD-28FW-L203 | Counter-clockwise | |

| FFD-28SS-R102 | 0.1±0.01[N•m] (1±0.1kgf•cm) |

Clockwise |

| FFD-28SS-L102 | Counter-clockwise | |

| FFD-28SS-R502 | 0.5±0.05[N•m] (5±0.5kgf•cm) |

Clockwise |

| FFD-28SS-L502 | Counter-clockwise | |

| FFD-28SS-R103 | 1±0.1[N•m] (10±1kgf•cm) |

Clockwise |

| FFD-28SS-L103 | Counter-clockwise | |

| FFD-28SW-R103 | 1±0.1[N•m] (10±1kgf•cm) |

Clockwise |

| FFD-28SW-L103 | Counter-clockwise | |

| FFD-28SW-R153 | 1.5±0.15[N•m] (15±1.5kgf•cm) |

Clockwise |

| FFD-28SW-L153 | Counter-clockwise | |

| FFD-28SW-R203 | 2±0.2[N•m] (20±2kgf•cm) |

Clockwise |

| FFD-28SW-L203 | Counter-clockwise |

*) Rated torque is measured at a rotation speed of 20rpm at 20~25˚C