| Model | Load [kg] |

Thrust [N] |

Impact rate [m/sec] |

Motion time [sec] |

Recovering power of the piston rod [N] |

Bottom color * |

|---|---|---|---|---|---|---|

| FPD-1070B1-□W | 10 | 5 | 0.5 | 0.3~2.0 | 1.5 or less | Black |

| FPD-1070B2-□W | 15 | 8 | 0.5 | 0.4~2.2 | 1.5 or less | White |

| FPD-1070B3-□W | 15 | 13 |

0.5 | 0.5~2.5 | 1.5 or less | Gray |

| FPD-1060A1-□W | 10 | 8 | 0.5 | 0.3~2.0 | 6.0 or less | Black |

| FPD-1060A2-□W | 10 | 10 | 0.5 | 0.4~2.2 | 6.0 or less | White |

| FPD-1060A3-□W | 10 | 15 | 0.5 | 0.5~2.5 | 6.0 or less | Gray |

| FPD-1050A1-□W | 10 | 8 | 0.5 | 0.3~2.0 | 6.0 or less | Black |

| FPD-1050A2-□W | 10 | 10 | 0.5 | 0.4~2.2 | 6.0 or less | White |

| FPD-1050A3-□W | 10 | 15 | 0.5 | 0.5~2.5 | 6.0 or less | Gray |

| FPD-1050B1-□W | 10 | 5 | 0.5 | 0.3~2.0 | 1.5 or less | Black |

| FPD-1050B2-□W | 15 | 8 | 0.5 | 0.4~2.2 | 1.5 or less | White |

| FPD-1050B3-□W | 15 | 13 | 0.5 | 0.5~2.5 | 1.5 or less | Gray |

| FPD-1030A1-□W | 10 | 6 | 0.3 | 0.2~1.5 | 5.0 or less | Black |

| FPD-1030A2-□W | 10 | 8 | 0.3 | 0.2~1.5 | 5.0 or less | White |

| FPD-1030A3-□W | 10 | 13 | 0.3 | 0.3~1.6 | 5.0 or less | Gray |

| FPD-1030B1-□W | 10 | 5 | 0.3 | 0.2~1.2 | 1.5 or less | Black |

| FPD-1030B2-□W | 10 | 8 | 0.3 | 0.2~1.2 | 1.5 or less | White |

| FPD-1030B3-□W | 10 | 13 | 0.3 | 0.3~1.3 | 1.5 or less | Gray |

The above performance was measured using TKʼs instruments. So, please select dampers accordingly, and confirm operation on actual machines before selecting final models.

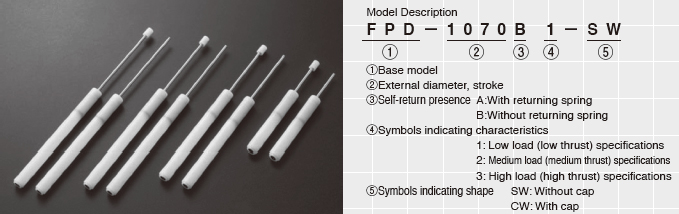

| Stroke [mm] | FPD-1070=70mm,FPD-1060=60mm,FPD-1050=50mm,FPD-1030=30mm |

|---|---|

| External diameter [mm] | ø10 |

| Mass [g] | FPD-1070-SW=13.5g,FPD-1070-CW=14g,FPD-1060-SW=13.5g,FPD-1060-CW=14g FPD-1050-SW=12g,FPD-1050-CW=12.5g,FPD-1030-SW=8g,FPD-1030-CW=8.5g |

| Main unit material | Resin |

| Operating temperature [˚C] | 5~40 |

*The FPD-1070B series can be sold only without the spring.

*The FPD-1060A series can be sold only with the spring.

*E-type retaining ring (nominal 2) can be attached to top of S type (A in above drawing).

*Do not use this product without carefully reading the attached ownerʼs manual.

*Use with an external stopper.

*Ensure that sufficient mounting strength is secured for this product.

*2 or more of this product can be used in parallel.

*Do not use this product in a vacuum or a location where it may come in contact with oil.

*Ensure that an eccentric load (lateral load) is not applied to the soft absorber.

*Do not pull the piston rod of the soft absorber more than stroke.

(This will cause air to get inside the soft absorber, causing ineffective stroke, abnormal sounds, and other damage to the soft absorber.)

*Do not push the piston rod of the soft absorber more than stroke.

*(This will cause recovery failure and other damage to the soft absorber.)